That makes sense. The throttle cable had a little ball at the end of it that I had to cut off. I didn't trim any sleeving off. I'll check that.Send pic, looking down. You might have to trim some of the black outer cover back to expose more of the wire cable. This will giv you more movement for the pedal, without being too tight, high idle.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need setup advice

- Thread starter joshw0000

- Start date

BaconBitRacing

Well-known member

I’m happy you’ll stick around! @BrownStainRacing really did put in everything he had, and you did a good job, and the effort was worth it!That makes sense. The throttle cable had a little ball at the end of it that I had to cut off. I didn't trim any sleeving off. I'll check that.

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

There should be an adjustment somewhere in the cable. Jus follow cable up to foot pedal. You don't need extra spring to pull it back, if adjusted right.That makes sense. The throttle cable had a little ball at the end of it that I had to cut off. I didn't trim any sleeving off. I'll check that.

Looking forward to seeing vid of kids ripping it.

If its too much for the kids, you can turn the throttle stop screw in to slow em down. Dont mess with the governor spring you moved over.

Check that hemi to make sure the spring is in the right location and throttle stop screw is not touching.

You might as well take that p.i.t.a. tank off the hemi. I hate those stupid f 'ing tanks, they always in the dam way. Everything is sooooooooo much easier to get to, when you take them off and throw across the dam fence.

Did I mention????.... I dont like those gas tanks,

I actually have a little extra cable here. I'll tinker with it later. Got dad duty to run the kiddos around for a little bit.Send pic, looking down. You might have to trim some of the black outer cover back to expose more of the wire cable. This will giv you more movement for the pedal, without being too tight, high idle.

Attachments

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

Yeap, I understand that.I actually have a little extra cable here. I'll tinker with it later. Got dad duty to run the kiddos around for a little bit.

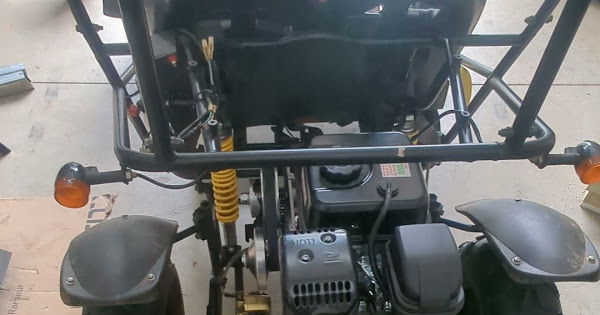

From this pic, jus loosen screw holding clamp (hold down) and let some of the black, outer cable, move in, till throttle moves all the way back to idle. Tighten screw to clamp (hold down). Move it from idle to WOT a few times to make sure everything returns. Ez, pz.

Yeap, I understand that.

From this pic, jus loosen screw holding clamp (hold down) and let some of the black, outer cable, move in, till throttle moves all the way back to idle. Tighten screw to clamp (hold down). Move it from idle to WOT a few times to make sure everything returns. Ez, pz.

My first launch was like that last night. The throttle was able to fully release. But with the pedal pressed the throttle only moved about half way. So I adjusted it so the pedal could fully throttle but it held the throttle up a little at idle. That's why I'm thinking a spring to pull it back at idle might be best. I picked up a pack at HF. When I have a chance to mess with it, I'll try some more to adjust it. Worst case, I just have to drill a small hole to attach the spring. It seems to be a pretty common remedy from what I've seen online.

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

It's worth a try, but I've never had to add another spring in, to pull throttle back that lil spring is more then enough. It's a very simple design.

There is a tension nut, that holds the levers together. It's a 10mm, thats in the middle of the assemble, sticky up. Giv it a 1/4- 1/2 turn ccw.

Looks to me the black part jus has to go in jus enough to let the throttle go back. It's not gonna take much.

I'll get a pic for you.

There is a tension nut, that holds the levers together. It's a 10mm, thats in the middle of the assemble, sticky up. Giv it a 1/4- 1/2 turn ccw.

Looks to me the black part jus has to go in jus enough to let the throttle go back. It's not gonna take much.

I'll get a pic for you.

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

The red straw is on the tension nut, give it a try. This nut is for utility machines that keeps the throttle at 1 speed, no up and down rpm.My first launch was like that last night. The throttle was able to fully release. But with the pedal pressed the throttle only moved about half way. So I adjusted it so the pedal could fully throttle but it held the throttle up a little at idle. That's why I'm thinking a spring to pull it back at idle might be best. I picked up a pack at HF. When I have a chance to mess with it, I'll try some more to adjust it. Worst case, I just have to drill a small hole to attach the spring. It seems to be a pretty common remedy from what I've seen online.

These cables have no tension between the hold down clamp and the lil screw that holds the wire cable, go's from idle to WOT and back, with jus that little stock return spring. The last 1 is really loose, but still goes to WOT.

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

Another thing. That 110cc original engine did NOT have an engine throttle stop screw to slow it down. They used a PEDAL stop screw.My first launch was like that last night. The throttle was able to fully release. But with the pedal pressed the throttle only moved about half way. So I adjusted it so the pedal could fully throttle but it held the throttle up a little at idle. That's why I'm thinking a spring to pull it back at idle might be best. I picked up a pack at HF. When I have a chance to mess with it, I'll try some more to adjust it. Worst case, I just have to drill a small hole to attach the spring. It seems to be a pretty common remedy from what I've seen online.

Go look up under the pedal. I bet you see some kinda bolt with a lock nut. Unlock the lock nut and adjust the bolt so you get the MOST movement from the pedal, idle to WOT. Then go back look at cable on engine. I still say you have to move the black part in a hair or 2.

Good info, thanks. I did loosen that stop screw some but I can back it out a little more. I'll also look at the pedal and see if there's some adjustments there. We had a last minute softball tournament today so it'll probably be late this evening before I can look at it. We're only on the 2nd pool game. The bracket hasn't even started yet.Another thing. That 110cc original engine did NOT have an engine throttle stop screw to slow it down. They used a PEDAL stop screw.

Go look up under the pedal. I bet you see some kinda bolt with a lock nut. Unlock the lock nut and adjust the bolt so you get the MOST movement from the pedal, idle to WOT. Then go back look at cable on engine. I still say you have to move the black part in a hair or 2.

You're right (again). This bolt was stopping the range of motion. I adjusted it all the way in so the throttle can be fully pressed and then fully reset. I think this will fix the throttle issue.Another thing. That 110cc original engine did NOT have an engine throttle stop screw to slow it down. They used a PEDAL stop screw.

Go look up under the pedal. I bet you see some kinda bolt with a lock nut. Unlock the lock nut and adjust the bolt so you get the MOST movement from the pedal, idle to WOT. Then go back look at cable on engine. I still say you have to move the black part in a hair or 2.

New video by Josh Walker

photos.app.goo.gl

photos.app.goo.gl

Attachments

Last edited:

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

That looks better. You should have 4200-4400 rpm now, before the governor starts pushing the throttle back.You're right (again). This bolt was stopping the range of motion. I adjusted it all the way in so the throttle can be fully pressed and then fully reset. I think this will fix the throttle issue.

New video by Josh Walker

photos.app.goo.gl

That tension nut looks too loose now.

It don't need to be locked down. But they are tangs that keep the parts lined up so everything works likes its supposed to. During bumpy rides, If that top piece pops up outta those tangs, it might cas it to go to WOT when it's not suppos to. Might wanna turn it back in a few turns and make sure the throttle still moves smoothly. Safety 1st.

I say them kids had you going all day.

My grandson came over for the week end. We cut some fallen trees outta the trails and done some riding. My butt is hurting today,

I'm still waiting on that "burnout on the shop floor" video,

I hope you and the kids have lots of fun today.

Today didn't start as I'd hoped. I intended to take a few test laps and set the kids loose on it. About the 3rd lap, the chain popped off. I put it back on and adjusted the motor some. A couple laps later it popped off again.That looks better. You should have 4200-4400 rpm now, before the governor starts pushing the throttle back.

That tension nut looks too loose now.

It don't need to be locked down. But they are tangs that keep the parts lined up so everything works likes its supposed to. During bumpy rides, If that top piece pops up outta those tangs, it might cas it to go to WOT when it's not suppos to. Might wanna turn it back in a few turns and make sure the throttle still moves smoothly. Safety 1st.

I say them kids had you going all day.

My grandson came over for the week end. We cut some fallen trees outta the trails and done some riding. My butt is hurting today,

I'm still waiting on that "burnout on the shop floor" video,

I hope you and the kids have lots of fun today.

I had very limited adjustability with how I mounted the motor so I ended up pulling it back off completely. I notched a few inches out of all 4 holes on the original motor mount plate, then mounted the motor back on the spacer tubes, reinstalled the chain, adjusted it and tightened everything back down. While I did that, the kids played on the four wheeler and my wife rode the mini bike. By the time I finished, the girls had lost interest and went to their grandparents house.

Once I finished, my wife wanted to ride it so I followed her for several laps around the yard (on the mini bike) without any issues. I then rode it, and tried a few hard launches (which seems to have stretched/loosened the chain again), did some donuts, and drove around the yard for about 15-20 mins. Since the kids were gone, I decided to do what I'd never let them do, and take it down the road. It maxes out at 31 MPH. I could only get to about 17 MPH in the yard, due to not being 100% level, turns, etc. I think that's plenty for them considering it gets up to speed fast.

New video by Josh Walker

photos.app.goo.gl

photos.app.goo.gl

On a bright note, I paid closer attention to the mini bike and realized it also has a hemi 212. Another reason it's so fast.

When the kids get home I'll let them ride the go kart. I'm going to adjust the chain again and tinker with the new cart. The new carb isn't inyet , I haven't ordered any needed parts, and our 80 lb puppy (which I've nicknamed demon dog) ate the belt (6" driven) I was going to use for it.

BaconBitRacing

Well-known member

Ask @Denny about dogs being trouble. I’ve got a hemi 212 as well, nice that the kart I’d going good. 31 is pretty good for no mods! It could probably go pretty good with a built engine…Today didn't start as I'd hoped. I intended to take a few test laps and set the kids loose on it. About the 3rd lap, the chain popped off. I put it back on and adjusted the motor some. A couple laps later it popped off again.

I had very limited adjustability with how I mounted the motor so I ended up pulling it back off completely. I notched a few inches out of all 4 holes on the original motor mount plate, then mounted the motor back on the spacer tubes, reinstalled the chain, adjusted it and tightened everything back down. While I did that, the kids played on the four wheeler and my wife rode the mini bike. By the time I finished, the girls had lost interest and went to their grandparents house.

Once I finished, my wife wanted to ride it so I followed her for several laps around the yard (on the mini bike) without any issues. I then rode it, and tried a few hard launches (which seems to have stretched/loosened the chain again), did some donuts, and drove around the yard for about 15-20 mins. Since the kids were gone, I decided to do what I'd never let them do, and take it down the road. It maxes out at 31 MPH. I could only get to about 17 MPH in the yard, due to not being 100% level, turns, etc. I think that's plenty for them considering it gets up to speed fast.

New video by Josh Walker

photos.app.goo.gl

On a bright note, I paid closer attention to the mini bike and realized it also has a hemi 212. Another reason it's so fast.

When the kids get home I'll let them ride the go kart. I'm going to adjust the chain again and tinker with the new cart. The new carb isn't inyet , I haven't ordered any needed parts, and our 80 lb puppy (which I've nicknamed demon dog) ate the belt (6" driven) I was going to use for it.

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

@joshw0000

Sounds jus lik a typical day in the...... gokart world. Until you get the bugs worked out. What you have done is a conversion/swap kinda deal, and you gonna have some bugs. I'm quite sure you will get em outta there.

I SEE BLACK MARKS!!!!! That counts as a burnout,

I also see alot of engine plate, mount, flex. Watch the vid over and over, you will see it. That's gonna cause problems with chain, sprockets. The tav is moving with the engine, so all that flex is not hurting the belt, that's a good thing.

I say you are hitting that axle with around 140 ft/lbs torq from a dead stop. That's a lot of pressure on the engine plate/mount, welds, bearings, sprockets, chain. They better be up to par, if not you will be throwing chains. Any kinda flex, cracks in welds, or frame will move those sprockets around.

A new chain needs around 1/2" play up and down, and will stretch a lil after jus a few mins of riding. After 3 or 4 times of adjusting to get that 1/2" back, it should be done stretching. Dont over tighten a chain, it's bad on jackshafts, sprockets, bearings. If something keeps throwing chains, look for flex somewhere, you will find it. I'm still concerned that 8t sprocket jus don't have enough bite on that chain, I could be wrong tho.

31 mph is impressive, I was thinking around 27, 28 with the not so perfect gear.

BTW, that dog is awesome, looks like a Tasmanian Tiger, and they suppose to be extinct,

Sounds jus lik a typical day in the...... gokart world. Until you get the bugs worked out. What you have done is a conversion/swap kinda deal, and you gonna have some bugs. I'm quite sure you will get em outta there.

I SEE BLACK MARKS!!!!! That counts as a burnout,

I also see alot of engine plate, mount, flex. Watch the vid over and over, you will see it. That's gonna cause problems with chain, sprockets. The tav is moving with the engine, so all that flex is not hurting the belt, that's a good thing.

I say you are hitting that axle with around 140 ft/lbs torq from a dead stop. That's a lot of pressure on the engine plate/mount, welds, bearings, sprockets, chain. They better be up to par, if not you will be throwing chains. Any kinda flex, cracks in welds, or frame will move those sprockets around.

A new chain needs around 1/2" play up and down, and will stretch a lil after jus a few mins of riding. After 3 or 4 times of adjusting to get that 1/2" back, it should be done stretching. Dont over tighten a chain, it's bad on jackshafts, sprockets, bearings. If something keeps throwing chains, look for flex somewhere, you will find it. I'm still concerned that 8t sprocket jus don't have enough bite on that chain, I could be wrong tho.

31 mph is impressive, I was thinking around 27, 28 with the not so perfect gear.

BTW, that dog is awesome, looks like a Tasmanian Tiger, and they suppose to be extinct,

Thanks. I just created a new post for the Yerf Dog.Ask @Denny about dogs being trouble. I’ve got a hemi 212 as well, nice that the kart I’d going good. 31 is pretty good for no mods! It could probably go pretty good with a built engine…

@joshw0000

Sounds jus lik a typical day in the...... gokart world. Until you get the bugs worked out. What you have done is a conversion/swap kinda deal, and you gonna have some bugs. I'm quite sure you will get em outta there.

I SEE BLACK MARKS!!!!! That counts as a burnout,

I also see alot of engine plate, mount, flex. Watch the vid over and over, you will see it. That's gonna cause problems with chain, sprockets. The tav is moving with the engine, so all that flex is not hurting the belt, that's a good thing.

I say you are hitting that axle with around 140 ft/lbs torq from a dead stop. That's a lot of pressure on the engine plate/mount, welds, bearings, sprockets, chain. They better be up to par, if not you will be throwing chains. Any kinda flex, cracks in welds, or frame will move those sprockets around.

A new chain needs around 1/2" play up and down, and will stretch a lil after jus a few mins of riding. After 3 or 4 times of adjusting to get that 1/2" back, it should be done stretching. Dont over tighten a chain, it's bad on jackshafts, sprockets, bearings. If something keeps throwing chains, look for flex somewhere, you will find it. I'm still concerned that 8t sprocket jus don't have enough bite on that chain, I could be wrong tho.

31 mph is impressive, I was thinking around 27, 28 with the not so perfect gear.

BTW, that dog is awesome, looks like a Tasmanian Tiger, and they suppose to be extinct,

That video I've been promising...

New video by Josh Walker

photos.app.goo.gl

photos.app.goo.gl

Unfortunately it was short lived. I adjusted the chain twice with them and twice it came off. Once it jumped, once it popped the master link.

I've adjusted the motor a half dozen times today and it just won't stay right. This last time I noticed that the chain is hitting the fins. So I'll have to take the torque converter off and shave it down some more. I also made a few changes in hopes that it will be less snatchy on a dig and not pull the chain loose. I screwed the throttle stopper back out some so they can't floor it (which is the only way they ride), moved the red spring back to the center hole, and swapped one of the white springs back for the original one. It's no longer doing burnouts but still takes off OK and has aplenty of upper speed.

I tried to manually flex the motor and I can't. Up/ down, side to side, it doesn't move if I push on it. I hope the issue is just the fins. When the chain is properly installed, it occasionally nicks them and gets loose again (stretch I assume. I seriously doubt the motor is moving in the mounting holes. I'm using washers, lock nuts, and nylon lock nuts.

I'll mess with it more this week or next weekend.

Oh yeah, the dog is a Treeing Tennessee Brindle. We went to the pound last year looking for another Boxer and someone had just surrendered him. He was very young and much smaller. We liked the brindle color but didn't know anything about the bread. A quick Google search said they were hunters and good with kids/other dogs. He's very loving but chews EVERYTHING. I can't count on both hands and toes the number of things he's destroyed. Some, multiple times. He really likes wiring.@joshw0000

Sounds jus lik a typical day in the...... gokart world. Until you get the bugs worked out. What you have done is a conversion/swap kinda deal, and you gonna have some bugs. I'm quite sure you will get em outta there.

I SEE BLACK MARKS!!!!! That counts as a burnout,

I also see alot of engine plate, mount, flex. Watch the vid over and over, you will see it. That's gonna cause problems with chain, sprockets. The tav is moving with the engine, so all that flex is not hurting the belt, that's a good thing.

I say you are hitting that axle with around 140 ft/lbs torq from a dead stop. That's a lot of pressure on the engine plate/mount, welds, bearings, sprockets, chain. They better be up to par, if not you will be throwing chains. Any kinda flex, cracks in welds, or frame will move those sprockets around.

A new chain needs around 1/2" play up and down, and will stretch a lil after jus a few mins of riding. After 3 or 4 times of adjusting to get that 1/2" back, it should be done stretching. Dont over tighten a chain, it's bad on jackshafts, sprockets, bearings. If something keeps throwing chains, look for flex somewhere, you will find it. I'm still concerned that 8t sprocket jus don't have enough bite on that chain, I could be wrong tho.

31 mph is impressive, I was thinking around 27, 28 with the not so perfect gear.

BTW, that dog is awesome, looks like a Tasmanian Tiger, and they suppose to be extinct,

BrownStainRacing

Well-known member

- Messages

- 1,365

- Reaction score

- 1,350

Before you pull the tav plate off, get the driver and belt outta the way. Reach down and get a handful of both chains, and squeeze together. You should see where the flex is coming from. Or try a big pair of channel locks around both chains, make sure chain is tight. I'm sure you will see something move.That video I've been promising...

New video by Josh Walker

photos.app.goo.gl

Unfortunately it was short lived. I adjusted the chain twice with them and twice it came off. Once it jumped, once it popped the master link.

I've adjusted the motor a half dozen times today and it just won't stay right. This last time I noticed that the chain is hitting the fins. So I'll have to take the torque converter off and shave it down some more. I also made a few changes in hopes that it will be less snatchy on a dig and not pull the chain loose. I screwed the throttle stopper back out some so they can't floor it (which is the only way they ride), moved the red spring back to the center hole, and swapped one of the white springs back for the original one. It's no longer doing burnouts but still takes off OK and has aplenty of upper speed.

I tried to manually flex the motor and I can't. Up/ down, side to side, it doesn't move if I push on it. I hope the issue is just the fins. When the chain is properly installed, it occasionally nicks them and gets loose again (stretch I assume. I seriously doubt the motor is moving in the mounting holes. I'm using washers, lock nuts, and nylon lock nuts.

I'll mess with it more this week or next weekend.

How thick was that square tubing????

These lil motors will twist and bend steel if anything is flexing. It jus gets worse and worse.

Yea that puppy is cool. I've never seen 1 like that. I know all about crap getting destroyed