r97

Measure twice cut once

Ok, so before I put my newly acquired engine in a buggy frame I want to get it in good condition first.... rebuild time! Here is the basic plan:

-Remove from motorcycle (check!)

-Disassemble engine

-Clean ALL parts

-Strip and re-paint engine cases

-Rebuild starter motor

-Replace all gaskets

-Reassemble engine

I'm hoping to avoid getting new clutch plates, or piston rings as those are pretty expensive. The stupid gasket set is already $125, and that's not even including the $99 twin carb and fuel pump kit! Piston rings will run me $130... I already need to buy paint, and lots of pipes.

Anyhow, I'm going to try and save as many gaskets as I can, and not touch the carb until I know as a fact that they do not work.

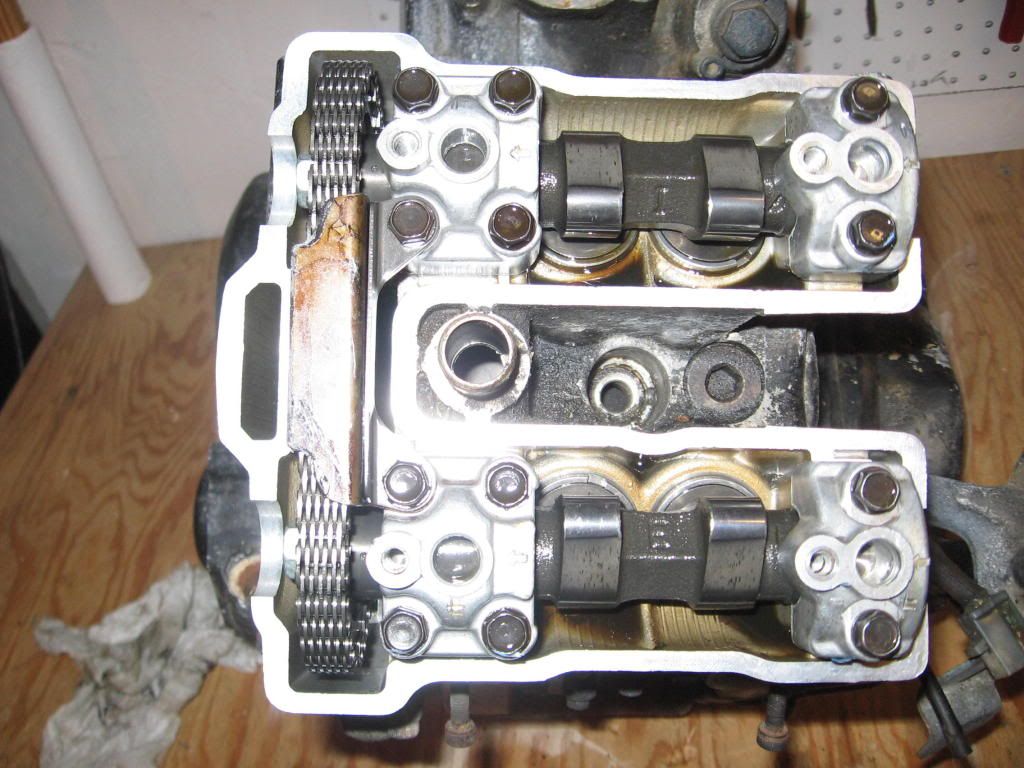

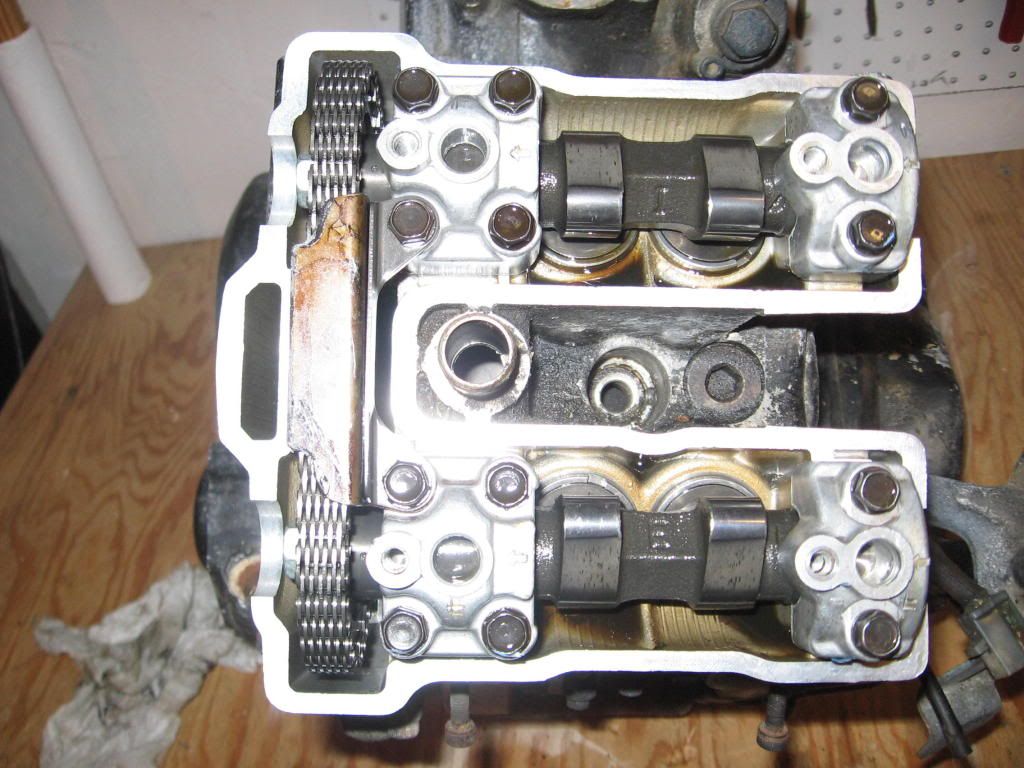

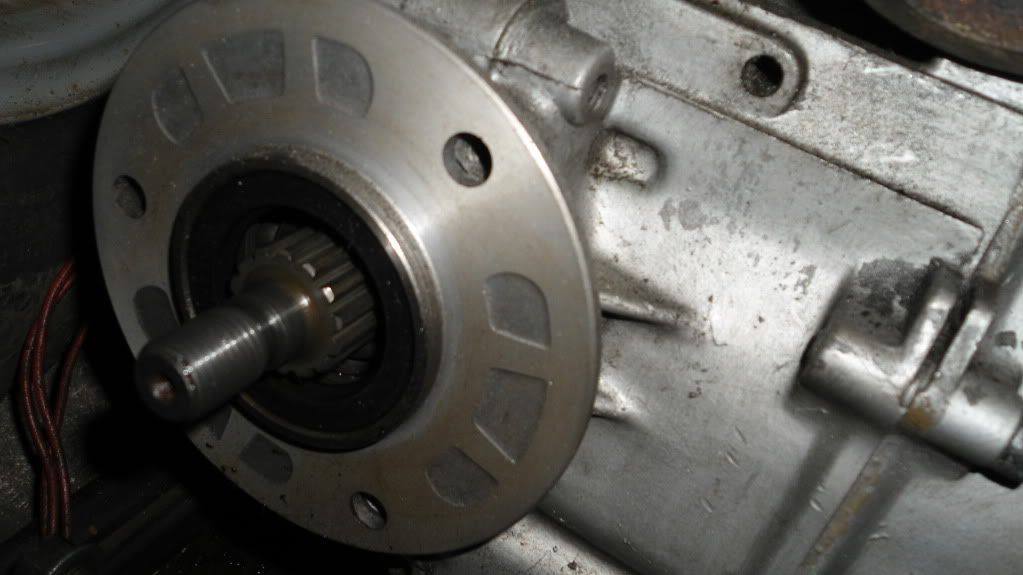

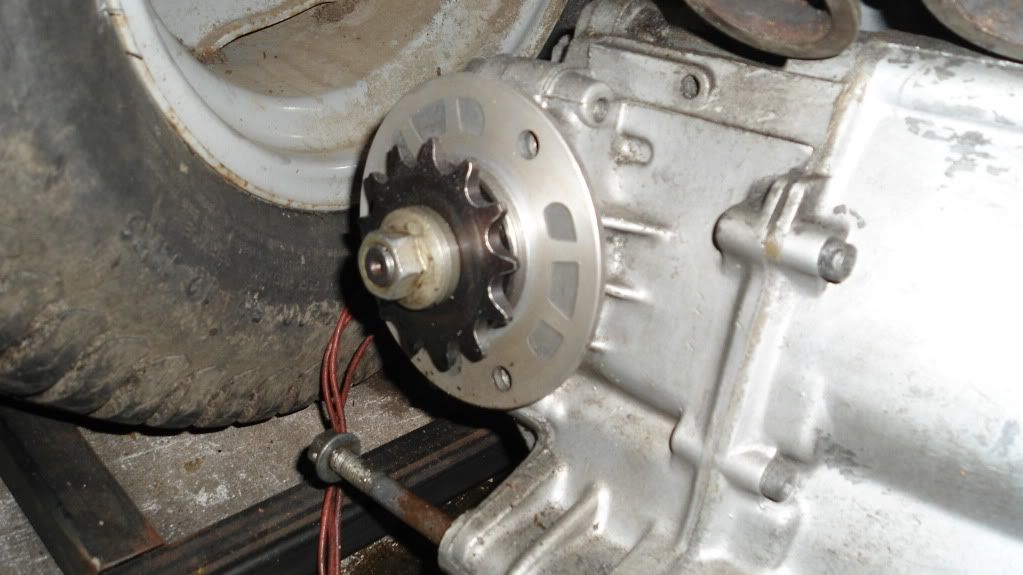

Here's some pics! Engine is a 552cc V-twin, liquid cooled, four stroke, DOHC, 4 valve, electric start, 5 speed manual, shaft drive, twin downdraft carb, 83' Yamaha!

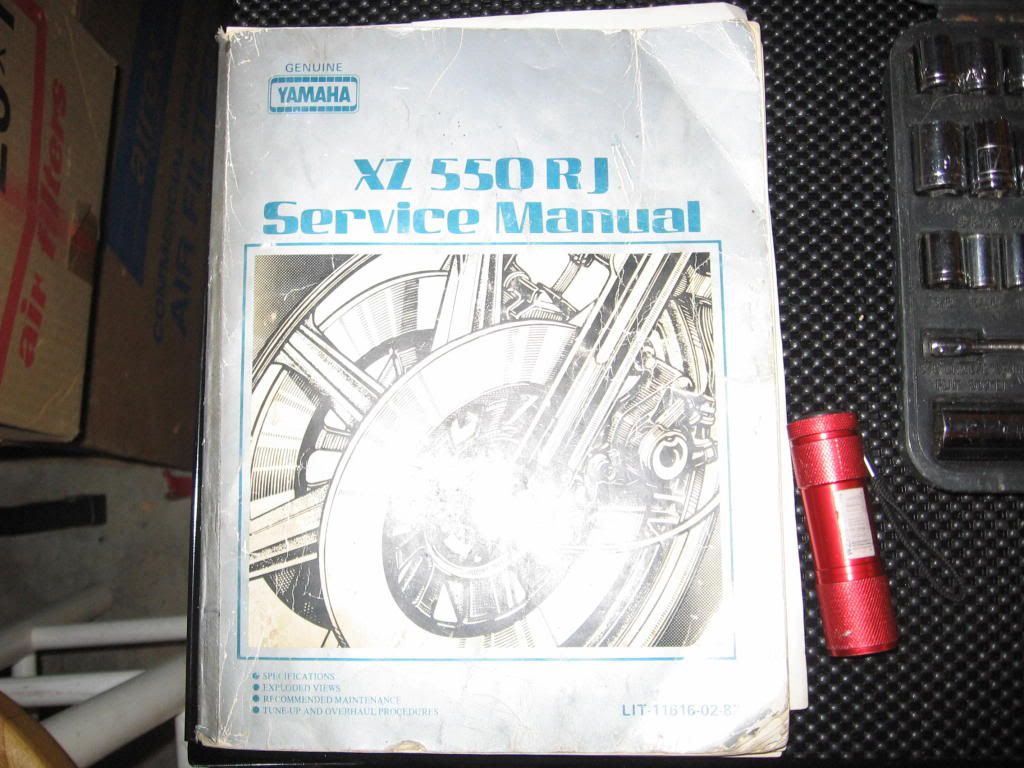

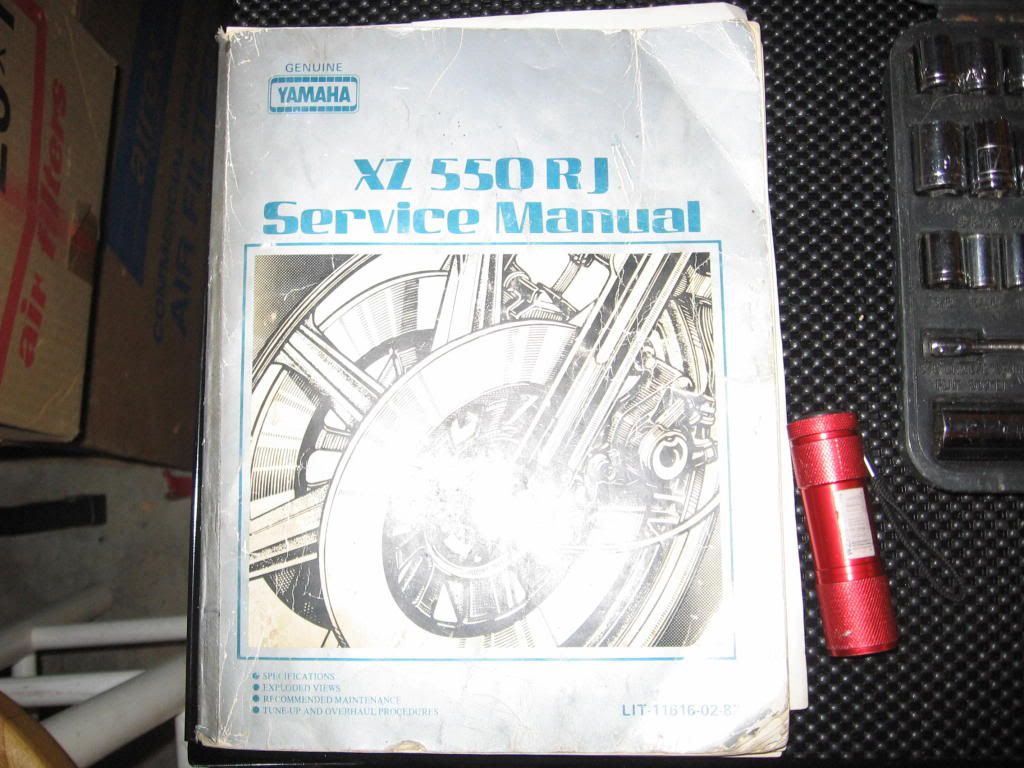

And of course the most important tool.....

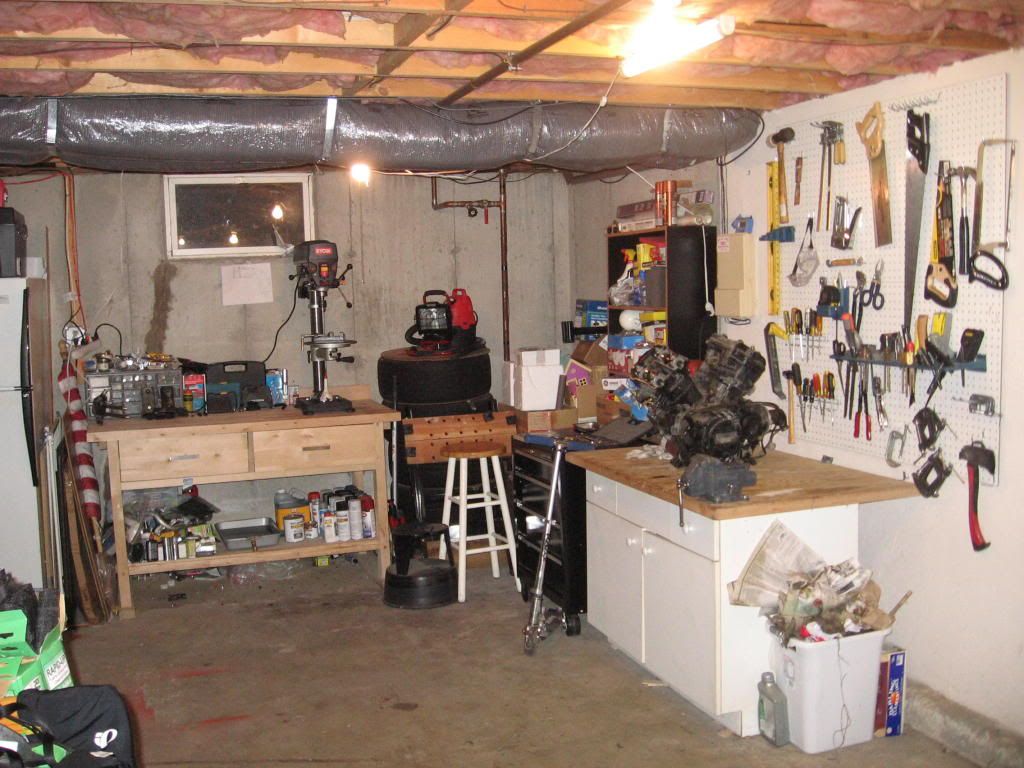

I'm noticing now that I have acquired a lot of parts! Most are from the motorcycle, and my go kart (disassembled), but not all. ATV tries and rims were scored almost new for $100!

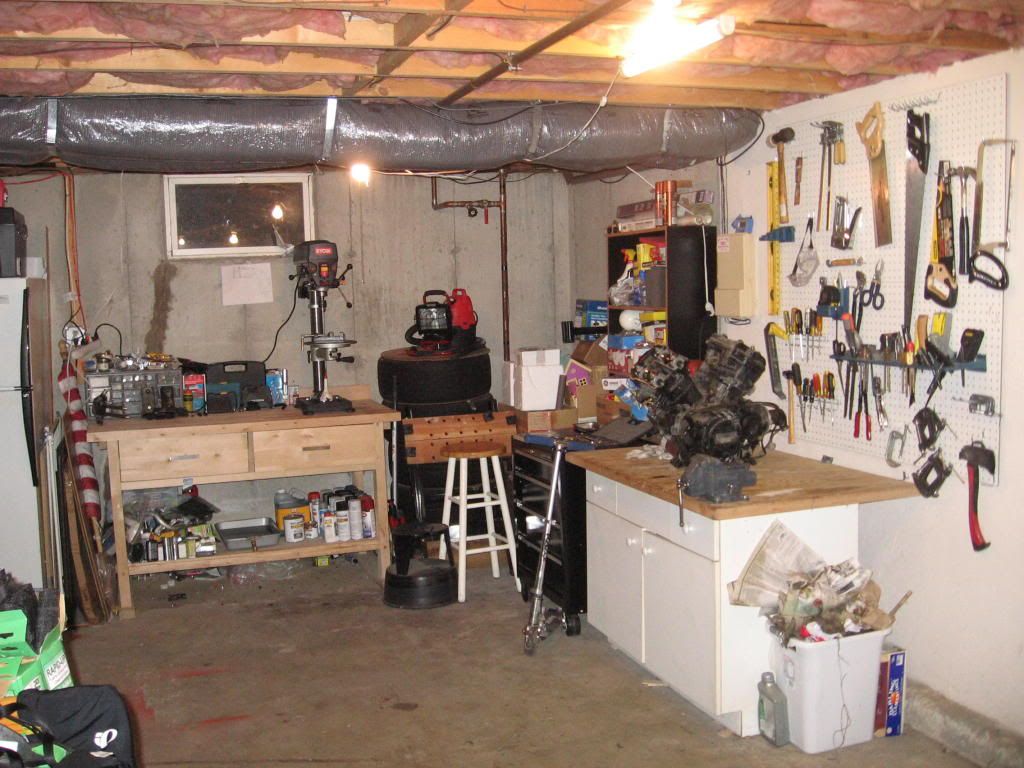

Also some upgrades to the shop! I cleaned it up nicely, and was given a big tool chest for Christmas (how did I live without it!?). I threw in a picture of my welding cart too, just need to make the gas cylinder mounts and a welding table so I can start my build!

-Remove from motorcycle (check!)

-Disassemble engine

-Clean ALL parts

-Strip and re-paint engine cases

-Rebuild starter motor

-Replace all gaskets

-Reassemble engine

I'm hoping to avoid getting new clutch plates, or piston rings as those are pretty expensive. The stupid gasket set is already $125, and that's not even including the $99 twin carb and fuel pump kit! Piston rings will run me $130... I already need to buy paint, and lots of pipes.

Anyhow, I'm going to try and save as many gaskets as I can, and not touch the carb until I know as a fact that they do not work.

Here's some pics! Engine is a 552cc V-twin, liquid cooled, four stroke, DOHC, 4 valve, electric start, 5 speed manual, shaft drive, twin downdraft carb, 83' Yamaha!

And of course the most important tool.....

I'm noticing now that I have acquired a lot of parts! Most are from the motorcycle, and my go kart (disassembled), but not all. ATV tries and rims were scored almost new for $100!

Also some upgrades to the shop! I cleaned it up nicely, and was given a big tool chest for Christmas (how did I live without it!?). I threw in a picture of my welding cart too, just need to make the gas cylinder mounts and a welding table so I can start my build!

, there was a bunch of blue gasket maker crap too.

, there was a bunch of blue gasket maker crap too.

Okay then. Why have many 4 stroke MB engines I have played with had a master links?

Okay then. Why have many 4 stroke MB engines I have played with had a master links? . Cam bearings? This thing is just metal on metal! Of course there are 2 1/2" pressurized oil passages running through each cam!

. Cam bearings? This thing is just metal on metal! Of course there are 2 1/2" pressurized oil passages running through each cam!