So I sold some stuff I had laying around and raised some cash for a kart. It is going to be a full suspension kart, double a arms on the front and the rear will be a swing arm, pretty standard. The engine though will sit on its own little shelf behind the rider and won't bob up and down with the tires. I will utilize a chain tensioner I am going to make to facilitate adjusting to the changes caused in the chain. The tires are going to be

http://www.bmikarts.com/item/15-Super-Turf-Front-Tire-on-Silver-Rim-260045S-6942 obviously the rear tires for the rear.

It is going to be powered by a 7-8hp engine with a 12 tooth sprocket clutch going to a 60t sprocket. I will be using a mechanical disc brake system on an 8 inch brake rotor. It will be live axle straight across. The seat will be a standard lawn mower seat cause shipping on seats is expensive!

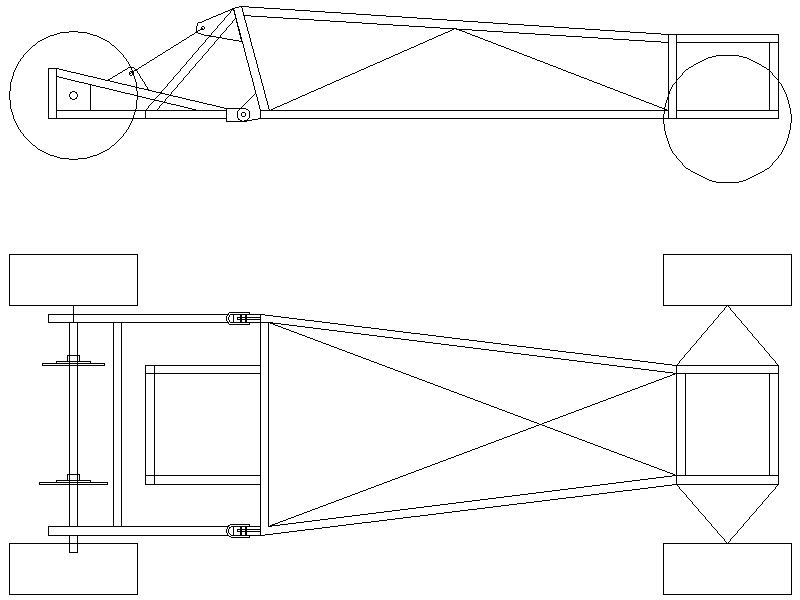

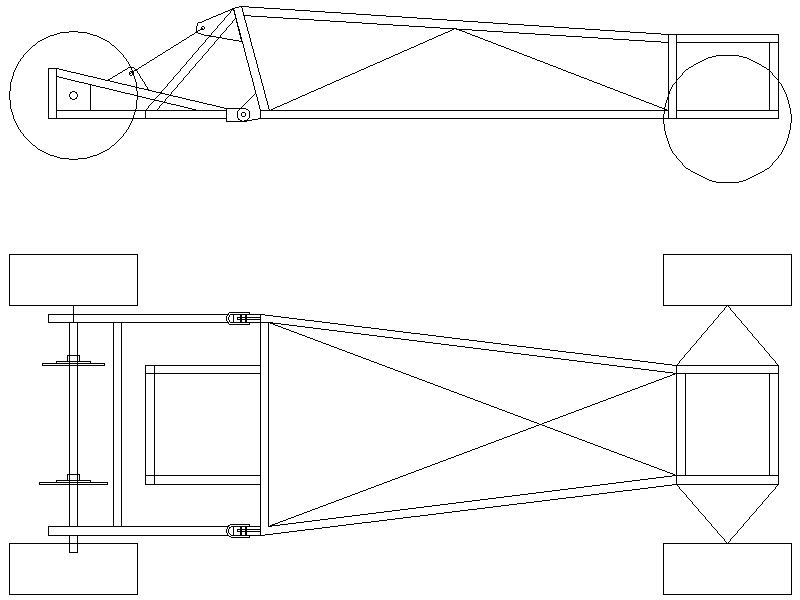

Here is the initial design idea:

It is 77 inches long from wheel center to wheel center right now. The seating area is 24 inches wide tapering down to 12 inches wide and is 48 inches long. I'm kind of tall at 6 feet and I don't like being scrunched up. The seat will be adjustable. The tubing is going to be 1x1x.083 and I'm considering making the bottom rail 2x1 for extra strength, though I'm not sure it will be needed.

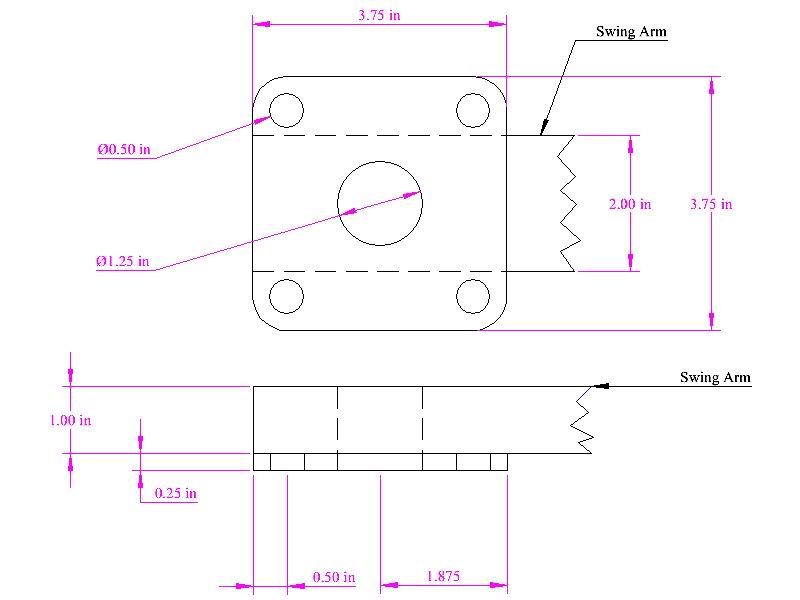

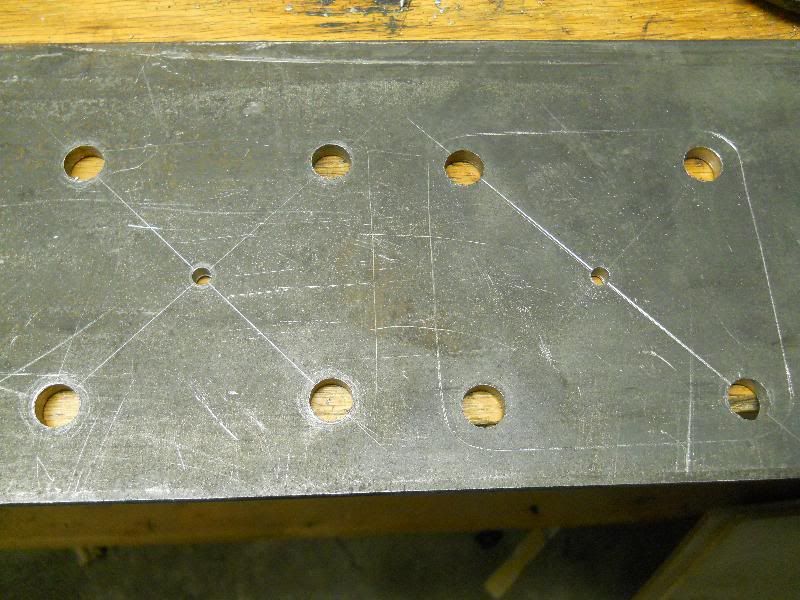

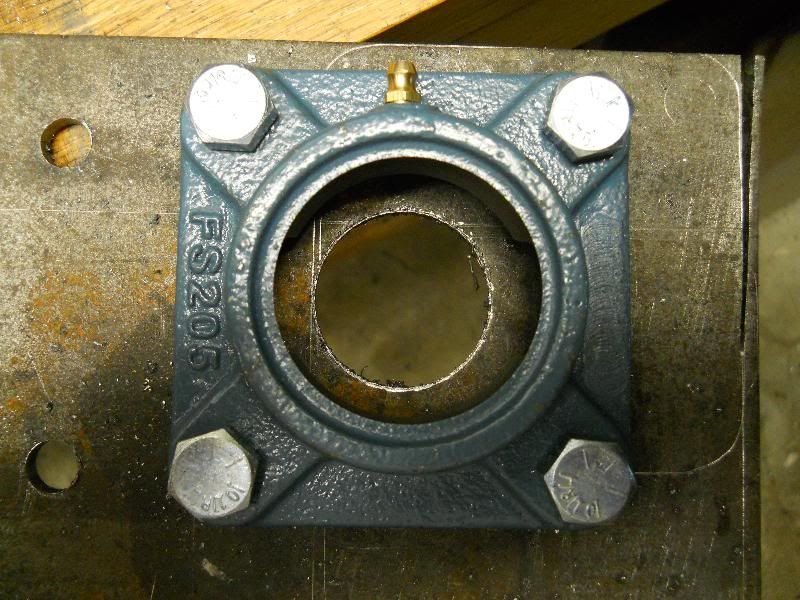

I am going to make some changes, namely to the rear section. Going to make it a tad shorter and the swing arms are going to be made out of 2x1 rectangle tube. At the ends I will weld on 1/4" plate to mount a flange bearing block and the axle will run through the swing arm. That way I can get more ground clearance.

The shocks im going to use are just simple cheap mechanical shocks, each rated at 450 pounds with 2" of travel. Total suspension weight would be 1800 lbs then.

I hope to talk to a friend and utilize his machining tools to make a lot of the parts myself like the hubs, axle, and spindles. Now I'm just waiting on my tires and what nots to get here so I can get measurements from them so I can design the fine details like the spindle and suspension and spacers i will need to get the rear tires spaced from the frame the distance I want.

I plan to document the entire build for everyone's enjoyment.

http://www.bmikarts.com/item/15-Super-Turf-Front-Tire-on-Silver-Rim-260045S-6942 obviously the rear tires for the rear.

It is going to be powered by a 7-8hp engine with a 12 tooth sprocket clutch going to a 60t sprocket. I will be using a mechanical disc brake system on an 8 inch brake rotor. It will be live axle straight across. The seat will be a standard lawn mower seat cause shipping on seats is expensive!

Here is the initial design idea:

It is 77 inches long from wheel center to wheel center right now. The seating area is 24 inches wide tapering down to 12 inches wide and is 48 inches long. I'm kind of tall at 6 feet and I don't like being scrunched up. The seat will be adjustable. The tubing is going to be 1x1x.083 and I'm considering making the bottom rail 2x1 for extra strength, though I'm not sure it will be needed.

I am going to make some changes, namely to the rear section. Going to make it a tad shorter and the swing arms are going to be made out of 2x1 rectangle tube. At the ends I will weld on 1/4" plate to mount a flange bearing block and the axle will run through the swing arm. That way I can get more ground clearance.

The shocks im going to use are just simple cheap mechanical shocks, each rated at 450 pounds with 2" of travel. Total suspension weight would be 1800 lbs then.

I hope to talk to a friend and utilize his machining tools to make a lot of the parts myself like the hubs, axle, and spindles. Now I'm just waiting on my tires and what nots to get here so I can get measurements from them so I can design the fine details like the spindle and suspension and spacers i will need to get the rear tires spaced from the frame the distance I want.

I plan to document the entire build for everyone's enjoyment.