Would you mind giving us an update on what you settled on for a motor mount? I'm considering this engine, but want to plan everything out before pulling the trigger.

Also, what kind of motor/axle sprockets did you use? I'm having a **** of a time finding sprockets for the 20mm shaft bore with a 5mm key. And an even harder time finding axle sprockets to match the limited motor sprockets I've seen!

Hi Josh,

sorry to have kept you hanging. I've finished my project a while ago and I'm extremely happy with the result. The motor has a lot of power, at least when coupled with LiPo's that provide it with the necessary voltage. I'm considering making a video that shows the process that I went through when building the vehicle.

Until then - in case you haven't made your choice yet, or someone else arrives at this problem - here's how I managed to get a mount and sprocket that fit the HPM3000:

There are several mounts available on

https://www.kit-elec-shop.com/gb/ and

https://evea-kartmasters.fr/en/ You can ask them to provide you with a custom mount that will fit the HPM3000, or you can drill the plate yourself when you receive it. Just be aware that a stainless steel plate will be much harder to drill than normal steel.

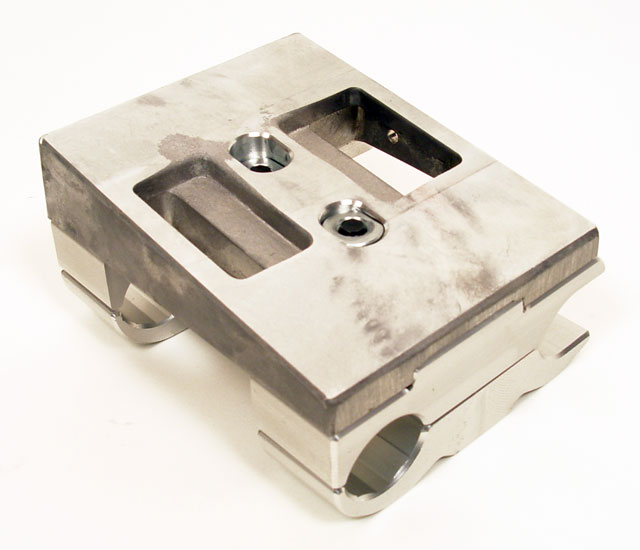

However, these mounts can be quite expensive. In my case the price amounted to about half of what I've paid for the frame (wheels, axles, rear sprocket, chain, and all). Therefore, I've decided to build one myself. Being a novice engineer, it was a very difficult task that took probably almost as much time in the end as doing ALL the electrical work - so keep that time/cost payoff in mind.

Have a look at the attachments for the my final design.

It's far from perfect. You need to take off the motor to readjust the chain tension. And doing so is not particularly easy to do either. But it works very well for the most part. Unfortunately, when putting a lot of torque on the sprockets, the chain sometimes falls off. Not sure whether that's due to the mount, or the sprocket. Speaking of which...

Indeed, it's a PITA to find a sprocket that matches the motor's shaft. In the end, I found an offer on ebay that almost fully suited my needs. It's not available anymore, but I've added a screenshot of the title in the attachment.

Maybe you'll be able to find something based on those keywords.

Now, why do I say that it "almost" suited my needs? Notice that the title of those offers says "3/4 Bore". This means that the hole in the sprocket has a 3/4 inch diameter. That's 19.05 mm. And the HPM3000's shaft is 20 mm. Whoops!

Sure enough, the sprockets didn't fit straight out of the box. But I was able to enlarge the bore a little using a drill with a carving bit, similar to the first one on the left of the pic in the attachments. Surely there has to be a more elegant and precise solution, but I couldn't come up with one in the little time I had.

And that's how I got a fitting sprocket. As for the rear axle, you just need to make sure that it's for the same chain type as the sprocket (the one I bought is a 219, which is quite popular) and that it has the right number of teeth for you preferred gear ratio.

I hope this helps. Good luck!

signal-attachment-2020-03-23-195527_010.jpeg453.7 KB · Views: 9

signal-attachment-2020-03-23-195527_010.jpeg453.7 KB · Views: 9 signal-attachment-2020-03-23-195527_008.jpeg444.9 KB · Views: 10

signal-attachment-2020-03-23-195527_008.jpeg444.9 KB · Views: 10 signal-attachment-2020-03-23-195527_007.jpeg414.8 KB · Views: 11

signal-attachment-2020-03-23-195527_007.jpeg414.8 KB · Views: 11 signal-attachment-2020-03-23-195527_009.jpeg337.5 KB · Views: 10

signal-attachment-2020-03-23-195527_009.jpeg337.5 KB · Views: 10 signal-attachment-2020-03-23-195527_012.jpeg511.4 KB · Views: 7

signal-attachment-2020-03-23-195527_012.jpeg511.4 KB · Views: 7 signal-attachment-2020-03-23-195527_005.jpeg496.2 KB · Views: 8

signal-attachment-2020-03-23-195527_005.jpeg496.2 KB · Views: 8