Idkw much 👍

Active member

Hi

ever since i got my go-kart I've grown about 10" and i don't really fit anymore, i do but it's hard to turn from how close my knees are to my steering

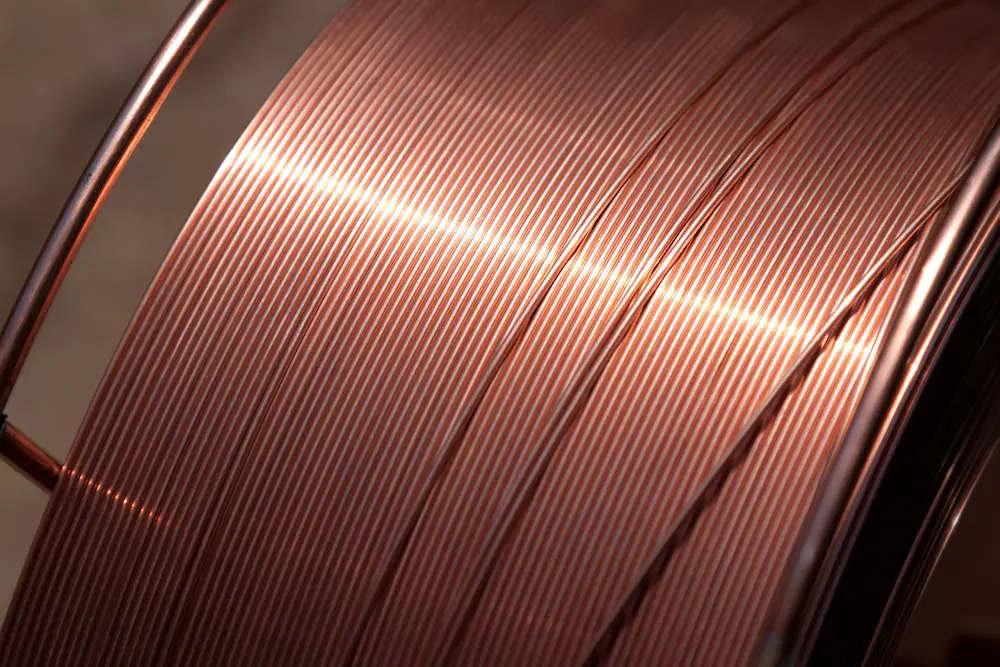

so i want to cut it( i also need help deciding where) and i wnated to do the welding meself cause i just thought it'd be more fun and cheaper this way,also to learn a new skill.

i don't really kw what welder to get, im tryn to keep it cheap, and i would also like to kw how hard is it and if there's anything i should kw bout welding before i get started

any advice is appreciated

ever since i got my go-kart I've grown about 10" and i don't really fit anymore, i do but it's hard to turn from how close my knees are to my steering

so i want to cut it( i also need help deciding where) and i wnated to do the welding meself cause i just thought it'd be more fun and cheaper this way,also to learn a new skill.

i don't really kw what welder to get, im tryn to keep it cheap, and i would also like to kw how hard is it and if there's anything i should kw bout welding before i get started

any advice is appreciated