You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spider carts Grand Daddy build

- Thread starter LightningTeg

- Start date

So I'm trying to find the appropriate steering rack for the grand daddy. What did you use?

There is an 8.5" one on amazon:

But one review says the turn radius suffers, and that the 11" is more appropriate:

But that one has some bad reviews also.... referencing the angle of the hiem joints a few other things.

Neither of them are cheap.

My instinct is to go with the shorter one, because of the narrow front section of the frame. I'd want the pivot points of the steering rack to line up as close as possible with the A-arms to minimize bump steer.

Ideas anyone? There are also complete go-kart steering kits for cheap, but maybe they're not heavy duty enough for this.

There is an 8.5" one on amazon:

But one review says the turn radius suffers, and that the 11" is more appropriate:

But that one has some bad reviews also.... referencing the angle of the hiem joints a few other things.

Neither of them are cheap.

My instinct is to go with the shorter one, because of the narrow front section of the frame. I'd want the pivot points of the steering rack to line up as close as possible with the A-arms to minimize bump steer.

Ideas anyone? There are also complete go-kart steering kits for cheap, but maybe they're not heavy duty enough for this.

I bought my rack from " next Gen off road" , (google them) , about $100.00 shipped promptly, works perfectly on my arachnid.

Da Flash

Ah, thanks. Did you go with the 11" one? this one here:

11 INCH RACK, BILLET, THIN LINE 5/8-36 SHAFT AC425140 16-2180

www.nexgenoffroad.com

madprofessor

"Loose Cannon Creations"

Don't know what's causing your heat-weakened steel to crack, but consider the transmitting of vibration from the engine to the frame to the remote fuel tank.they keep cracking where I heated and bent them. Thinking of going with a 1 1/2" flat bar for more strength

I used (HARD) rubber motor mounting grommets from one (?) of the gokart parts suppliers between my engine and its mounting plate, but that wasn't good enough for my OCD. I used some (SOFT) rubber "grommets" I sliced out of rubber stoppers from Home Depot and drilled through to remote mount my fuel tank. Used the OEM standard 3 mounting points for a Predator 212 tank to some angle iron I welded on for the mounting. The soft rubber discs I'd made does a great job of preventing vibration to the fuel tank, therefore also reducing vibration stress on the angle iron the tank is bolted to.

Definitely make up some sort of vibrasorber for the tank, and also for the engine if there is none.

NOTE: Flat bar is only strong in one direction, flaps like my exes' gums in the other. ANGLE or otherwise not flat steel automatically provides strength in all directions. Also, don't rethink the hassle of remote mounting the tank, it's worth it. I have a fuel pump, shouldn't need any gravity at all, and remoted the tank high enough for gravity feed anyway, because it's worth it. Didn't want any draining of the lines during downtime, or any wasted preliminary pulls on the rope to get fuel to the carb.

madprofessor

"Loose Cannon Creations"

Hola Argentina George, and welcome. Your 7-year old boy's going to love it. I'd send you plans if I had some, but never have had any. The Spiderkarts plans cost money, but " kartfab.com " has free plans you can download to build a pretty nice kart.Hola estimado soy Jorge de argentina y tambien sueño con armar un grandaddy go kart para mi hijo de 7 años. Quisiera saber si alguien de ustedes me podría hacer el favor de pasarme el plano del chasis con todas sus medidas. Gracias. Cuando comience a armario les mandaré fotos. Saludos

You can make some of the plan measurements longer, shorter, wider, etc. to suit you if desired, the kartfab.com plans make it very easy to modify.

We are just about finished with the Spyder carts Granddaddy build, however are struggling with the steering. Does anyone have a suggestion which one to use? The one we bought was very cheap and quickly broke

View attachment 131859

Nice looking build!

Off the wall question... did you offset your A-arms to add a little rake to the spindles? I can't 100% tell from the picture, but it looks like they're parallel up and down?

AlexBatres86

New member

- Messages

- 12

- Reaction score

- 2

Nice looking kart! I’m half way through mine, did you go with the 13hp Predator?We are just about finished with the Spyder carts Granddaddy build, however are struggling with the steering. Does anyone have a suggestion which one to use? The one we bought was very cheap and quickly broke

View attachment 131859

AlexBatres86

New member

- Messages

- 12

- Reaction score

- 2

MTScottSo I'm trying to find the appropriate steering rack for the grand daddy. What did you use?

There is an 8.5" one on amazon:

But one review says the turn radius suffers, and that the 11" is more appropriate:

But that one has some bad reviews also.... referencing the angle of the hiem joints a few other things.

Neither of them are cheap.

My instinct is to go with the shorter one, because of the narrow front section of the frame. I'd want the pivot points of the steering rack to line up as close as possible with the A-arms to minimize bump steer.

Ideas anyone? There are also complete go-kart steering kits for cheap, but maybe they're not heavy duty enough for this.

Did you ever figured this out? I am looking to start working on the steering assembly for my grand daddy. Did you go with the 11” or the 8”?

How do they perform? What about the steering wheel shaft and linkages?

Thanks in advance.

I mentioned earlier in this conversation.....Use the rack and pinion from "Next Gen Offroad" they have an 8 inch and 11 inch. I believe the 11 inch has more travel, so that;s the one I use. These are made for off road sand buggy racing, so they are solid. They are about $100, but they ain't going to break, yeah that seems expensive, but what's it going to cost after you break 3 cheap ones, bust up rims etc.

Da Flash

Da Flash

AlexBatres86

New member

- Messages

- 12

- Reaction score

- 2

Much better

I plan on only using that inner position where the nut was welded so ignore the total lack of material left at the end of the spindle arm. It got a little bendy

Also learned throuhg this process having once side RH thread and the other LH makes adjustments ALOT easier lol

I apologize, I’m new to the forum and I’m still trying to figure out the threads.I mentioned earlier in this conversation.....Use the rack and pinion from "Next Gen Offroad" they have an 8 inch and 11 inch. I believe the 11 inch has more travel, so that;s the one I use. These are made for off road sand buggy racing, so they are solid. They are about $100, but they ain't going to break, yeah that seems expensive, but what's it going to cost after you break 3 cheap ones, bust up rims etc.

Da Flash

what about the shaft length? And tie rods? Any chance you have the links for those parts?

thanks

MTScott

Did you ever figured this out? I am looking to start working on the steering assembly for my grand daddy. Did you go with the 11” or the 8”?

How do they perform? What about the steering wheel shaft and linkages?

Thanks in advance.

I went with the 11" from nexgen as mentioned, and actually ended up with a second one I got off of ebay because it took 3 months to get the one from nexgen. They both ended up shipping the exact same day, so I didn't have a chance to cancel the order, and now I have two. As far as I can tell, they're both made by the same company, and seem well built. I will be doing some odd things with mine to avoid bump steer, but have not installed it yet, so I don't really know how it performs. I think it will do well...

AlexBatres86

New member

- Messages

- 12

- Reaction score

- 2

Good luck with your experiment! Hopefully you can get it where you want it.

go kart man

Member

- Messages

- 35

- Reaction score

- 21

What are the exact dimensions on thisHey everyone! New to forum, but I find myself here researching things often so figured I would start a build thread.

Started this project 3 months ago. I've always wanted a go kart / off road buggy when I was a kid but my dad would never let me have one because he didn't want me tearing up the lawn lol. Now I'm almost 30 and have the space to do what I want!

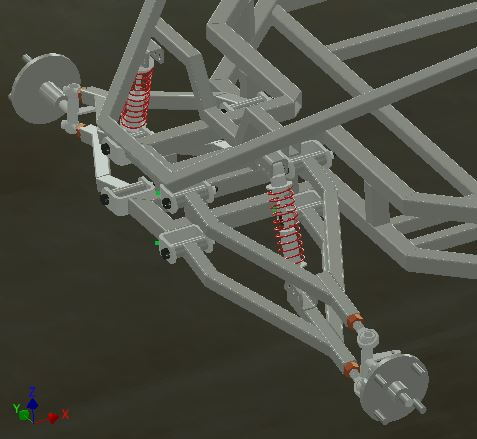

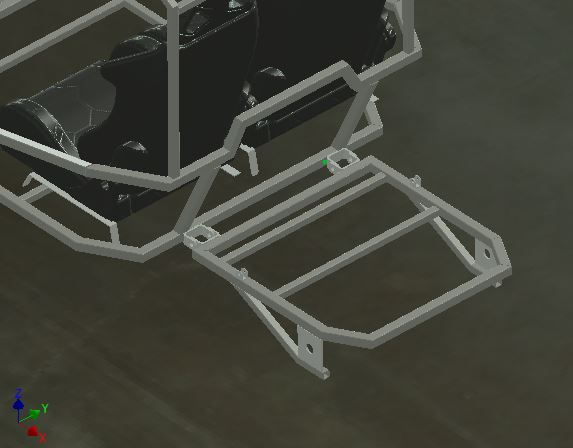

Did some digging and found the spider carts granddaddy plans and determined that was a good route. The plans themselves are OK, but as an engineer I felt the drawings / work instructions were lacking. I ended up modeling the entire thing and making it a bit wider to accommodate the car seats I got from a parts car. Most of the frame is MIGed although I decided to TIG the A arms to get some practice and because TIG forces one to take the extra time to get it right.

So far I've got quite a bit of the frame done. I just started cutting pieces for what I call the "rear module" that carries the engine and rear axle.

Which brings me to my first question:

Based on my model, I'm going to need a 52" L axle. I'm not sure where to get one that long and whether I should get a Solid/Tubular axle and AL or Steel. The plans call out for a 1-1/4" axle for the 10hp engine the author used. I plan on using a Predator 420cc (15hp/18trq) and probably doing some performance upgrades. What do you guys suggest for axle?

Heres some pics!