New guy here, last night I picked up a used go kart with a fiberglass Model T delivery van body.

From what I've found it started life as a promotional go kart raffled off by Krogers and looked like this:

Not much information out there about it, don't know how many were made or how rare it is. The one I picked up was heading down the rat rod path but that's not really my thing so that will change, I'm not going to restore it either, it is missing too many original parts and I don't want to be forever on the hunt for them.

My thing is more miniature scale versions of things, when I first got the go kart itch I was looking more towards the Shriner Model T parade cars but those were way out of my budget plus I wanted to have fun with something without feeling like I was taking away from it's value, or afraid to use it. So I ended up buying this!

I don't know what direction I'll go with it, I was thinking paddy wagon like this:

Which would translate roughly to this:

The body is actually in decent shape, just a couple minor cracks, it will eventually be repainted. The wing and side mirrors will go as well. Wheels and tires are getting ditched too, I'm leaning toward all four 4.80/4.00-8 trailer wheels/tires which will look more period correct being a little taller and skinnier.

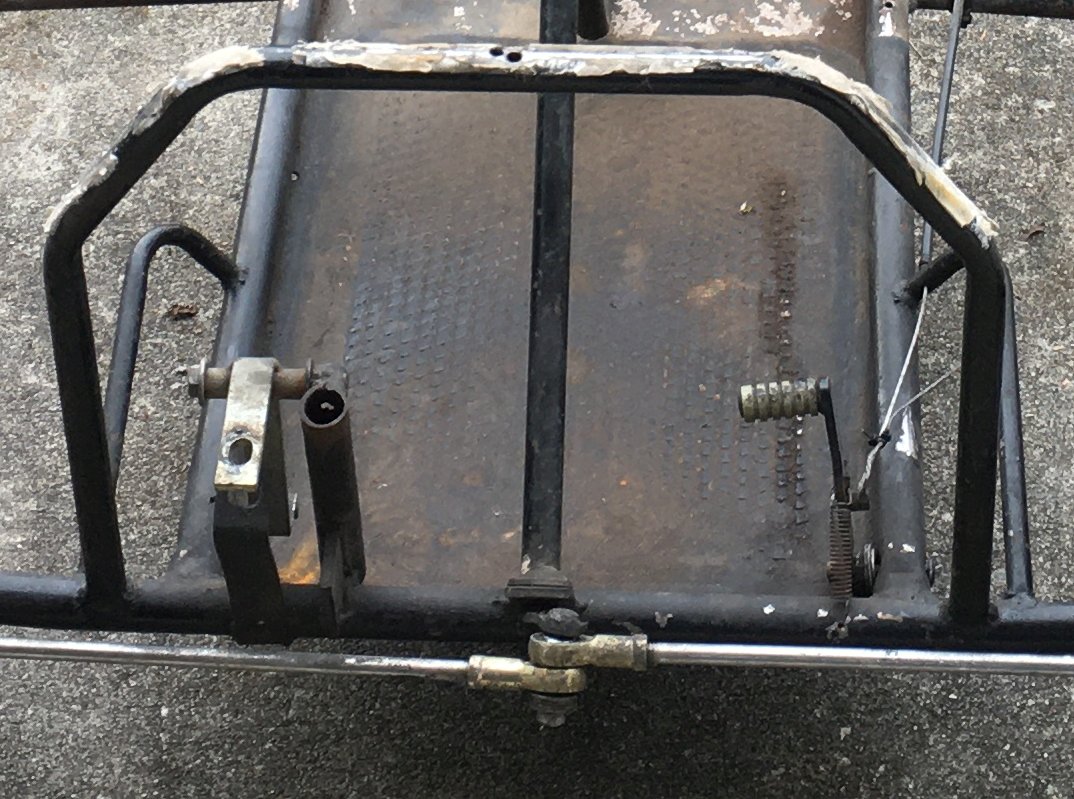

But first things first, I am going to get it running and go from there. I removed the non-original motor and gave it back to the guy when I bought it, I have a brand-new motor for it, and a new clutch is on the way. The frame clearly needs a little tweaking as well.

More to come!

Stewart

From what I've found it started life as a promotional go kart raffled off by Krogers and looked like this:

Not much information out there about it, don't know how many were made or how rare it is. The one I picked up was heading down the rat rod path but that's not really my thing so that will change, I'm not going to restore it either, it is missing too many original parts and I don't want to be forever on the hunt for them.

My thing is more miniature scale versions of things, when I first got the go kart itch I was looking more towards the Shriner Model T parade cars but those were way out of my budget plus I wanted to have fun with something without feeling like I was taking away from it's value, or afraid to use it. So I ended up buying this!

I don't know what direction I'll go with it, I was thinking paddy wagon like this:

Which would translate roughly to this:

The body is actually in decent shape, just a couple minor cracks, it will eventually be repainted. The wing and side mirrors will go as well. Wheels and tires are getting ditched too, I'm leaning toward all four 4.80/4.00-8 trailer wheels/tires which will look more period correct being a little taller and skinnier.

But first things first, I am going to get it running and go from there. I removed the non-original motor and gave it back to the guy when I bought it, I have a brand-new motor for it, and a new clutch is on the way. The frame clearly needs a little tweaking as well.

More to come!

Stewart

Last edited: